stihl 025 parts diagram pdf

The STIHL 025 parts diagram provides a detailed visual guide for identifying components, ensuring proper maintenance, and facilitating repairs. It helps users understand chainsaw assembly and functionality effectively.

1.1 Overview of the STIHL 025 Chainsaw

The STIHL 025 is a compact and reliable chainsaw designed for lightweight cutting tasks. It features a robust engine, durable motor housing, and user-friendly components like the quick chain tensioner. Known for its efficiency and portability, the 025 model is ideal for pruning and small-scale logging. Its design emphasizes ease of use and maintenance, making it a popular choice for both professionals and homeowners. Regular upkeep ensures optimal performance and longevity.

1.2 Importance of Using a Parts Diagram

A parts diagram is essential for understanding chainsaw components, ensuring proper maintenance, and facilitating accurate repairs. It provides a clear visual reference, helping users identify and locate parts efficiently. This tool minimizes guesswork during assembly or disassembly, reducing the risk of damage or incorrect installations. Regular use of the diagram ensures longevity and optimal performance of the STIHL 025 chainsaw.

Major Components of the STIHL 025

The STIHL 025 chainsaw features key components such as the engine, motor housing, quick chain tensioner, clutch, spur gear, air filter, muffler, and fuel system for optimal performance.

2.1 Engine and Motor Housing

The engine powers the chainsaw, while the motor housing protects internal components. Durable materials ensure longevity and performance. The parts diagram details these components, aiding in maintenance and repair by clearly identifying each part for easy reference and replacement, ensuring optimal functionality and safety during operation.

2.2 Quick Chain Tensioner

The quick chain tensioner simplifies chain adjustment, ensuring proper tension for efficient cutting. Located near the guide bar, it allows easy tightening or loosening without tools. The parts diagram highlights this mechanism, aiding users in identifying and replacing worn components. Regular maintenance of the tensioner prevents chain slippage and enhances saw performance, ensuring safety and precision during operation. Its design promotes ease of use and durability.

2.3 Clutch and Spur Gear

The clutch and spur gear are critical components, engaging the chain upon throttle activation. The diagram illustrates their assembly and function, enabling precise identification. Proper lubrication and alignment are essential for smooth operation. Wear or damage can lead to chain malfunction, emphasizing the need for regular inspection and timely replacement as shown in the parts diagram.

2.4 Air Filter and Muffler

The air filter ensures clean air intake, preventing engine damage, while the muffler reduces noise. The parts diagram details their locations and connections. Regular cleaning and replacement are crucial for optimal performance and engine longevity. Proper maintenance of these components is highlighted in the diagram to ensure efficient operation and reduce emissions effectively.

2.5 Fuel System

The fuel system, comprising the fuel tank, carburetor, and fuel lines, is essential for engine operation. The parts diagram illustrates connections and components, aiding in troubleshooting and maintenance. Regular inspection and cleaning ensure proper fuel flow, preventing engine issues and ensuring efficient performance. Proper maintenance is crucial for reliability and longevity of the fuel system.

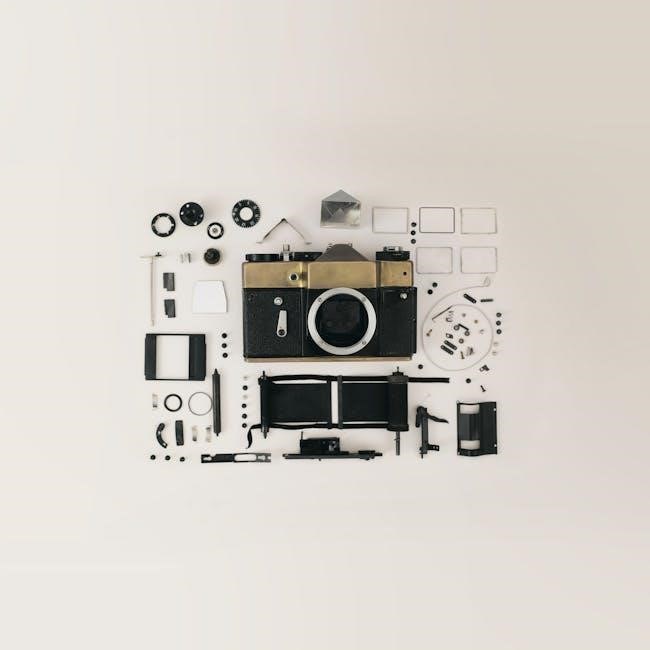

Detailed Parts Diagram Breakdown

The detailed parts diagram provides an exploded view of the STIHL 025, highlighting key components and their relationships. It serves as a visual roadmap for repairs and maintenance, ensuring accurate identification of parts and their functions.

3.1 Exploded View of the STIHL 025

The exploded view of the STIHL 025 provides a comprehensive visual representation of each component, showcasing how they are assembled. This detailed illustration helps users identify individual parts, such as the engine, motor housing, and clutch, and understand their spatial relationships within the chainsaw. It is an essential tool for repairs, maintenance, and assembly, ensuring accurate identification and reassembly of components.

3.2 Identifying Key Parts

The STIHL 025 parts diagram allows users to pinpoint essential components like the motor housing, quick chain tensioner, and clutch. By referencing the exploded view, individuals can accurately locate and identify parts, ensuring precise repairs and maintenance. This clarity is crucial for diagnosing issues and selecting the correct replacements, making the diagram an indispensable resource for chainsaw upkeep and functionality.

3.3 Understanding Assembly and Disassembly

The STIHL 025 parts diagram simplifies assembly and disassembly by providing a clear visual guide. Each component’s placement is illustrated, allowing users to understand how parts interconnect. The exploded view highlights the sequence of reassembly, ensuring accuracy. This resource is invaluable for DIY repairs, helping users avoid errors and potential damage to the chainsaw. It also aids in identifying worn or damaged parts efficiently.

How to Use the Parts Diagram

Navigate the diagram to identify components, match part numbers, and locate replacements. Use the visual guide to ensure accurate ordering and installation of STIHL 025 parts.

4.1 Navigating the Diagram

Start by locating the exploded view of the STIHL 025, which visually separates components. Use numbered labels to identify parts, cross-referencing with the provided list. Zoom in on specific sections for clarity and utilize the search function to quickly find items. This systematic approach ensures efficient navigation and accurate identification of required parts for repair or replacement.

4.2 Matching Parts Numbers

Each component in the STIHL 025 diagram is assigned a unique part number. When ordering replacements, ensure the numbers match exactly to avoid compatibility issues. Cross-check with the official parts list or consult an authorized dealer to confirm accuracy. This step is crucial for ensuring correct fitment and functionality of the chainsaw after repairs.

4.3 Ordering Replacement Parts

Once you’ve identified the required parts using the diagram, order them from authorized STIHL dealers or reputable online retailers like GHS. Ensure parts are genuine to maintain performance and warranty. Use the exact part numbers from the diagram to avoid mismatches. For convenience, some retailers offer bulk ordering options for frequent repairs, ensuring you always have essential components on hand.

Maintenance and Repair Tips

Regularly inspect and maintain your STIHL 025 using the parts diagram to identify wear. Clean the air filter and check the chain tension for optimal performance and longevity.

5.1 Regular Maintenance Routine

- Inspect the air filter and clean or replace it regularly to ensure proper engine performance.

- Check the chain tension and adjust as needed using the quick chain tensioner.

- Lubricate the chain and bar to prevent wear and tear.

- Clean the muffler and spark plug to maintain optimal engine function.

- Sharpen the chain regularly for efficient cutting and safety.

5.2 Common Parts Requiring Replacement

Regular wear and tear often necessitates replacing the air filter, chain, and spark plug. The clutch and spur gear may also require replacement due to heavy use or improper maintenance. Additionally, the quick chain tensioner and motor housing components can wear out over time. Ensure to refer to the parts diagram for accurate identification and ordering of genuine STIHL replacement parts.

5.3 Safety Precautions

Always wear protective gear, including gloves, safety glasses, and sturdy footwear. Ensure a firm grip on the chainsaw handles to prevent loss of control. Avoid operating the saw in wet or slippery conditions. Keep loose clothing and long hair tied back to prevent entanglement. Never use a chainsaw near open flames or sparks, and always follow proper shutdown procedures to avoid accidental start-ups.

Sources for the STIHL 025 Parts Diagram PDF

Access the STIHL 025 parts diagram through official STIHL websites, authorized dealers, or trusted online marketplaces like GHS, ensuring genuine and accurate documentation for your chainsaw.

6.1 Official STIHL Websites

Official STIHL websites offer authentic parts diagrams for the STIHL 025 chainsaw. These resources provide detailed, accurate exploded views and parts lists, ensuring users can identify components correctly. Accessing these diagrams directly from STIHL’s official platform guarantees reliability and compatibility, making it easier to order genuine replacement parts and maintain the chainsaw’s performance and safety standards effectively.

6.2 Authorized Dealers

Authorized STIHL dealers are trusted sources for the STIHL 025 parts diagram PDF. They provide genuine diagrams, expert support, and access to authentic parts. Users can download or request printed copies, ensuring accuracy for repairs. Dealers also offer guidance on interpreting the diagrams, making it easier to identify and purchase the correct components. This ensures compatibility and maintains the chainsaw’s performance and safety standards effectively.

6.3 Online Marketplaces

Online marketplaces like eBay, Amazon, and specialty tool sites offer downloadable PDFs of the STIHL 025 parts diagram. These platforms provide convenience and a wide selection of diagrams, often from verified sellers. Users can search by model number or specific parts, ensuring accurate results. Interactive diagrams on some sites also help users identify components visually, making it easier to find and purchase the correct parts efficiently.

Troubleshooting Common Issues

The STIHL 025 parts diagram aids in troubleshooting by visually identifying faulty components, guiding repairs, and ensuring correct part replacements for optimal chainsaw performance and longevity.

7.1 Identifying Faulty Parts

The STIHL 025 parts diagram is essential for identifying faulty components by providing a clear visual representation of the chainsaw’s structure. Users can locate worn or damaged parts, such as the clutch, spur gear, or bearings, by referencing the exploded view. This helps diagnose issues like unusual noises or poor performance, ensuring accurate repairs. Always cross-reference with the parts list for confirmation.

7.2 Using the Diagram for Diagnosis

The STIHL 025 parts diagram is a valuable tool for diagnosing issues by visually pinpointing potential problems. Users can trace mechanical issues, check for wear, and align symptoms with specific components. This detailed guide helps identify faulty parts, such as a damaged clutch or worn bearings, ensuring accurate troubleshooting and repair. It’s an essential resource for both DIY enthusiasts and professional technicians;

7.3 DIY Repair vs. Professional Service

Using the STIHL 025 parts diagram, users can determine if a repair is suitable for DIY or requires professional expertise. Simple fixes like replacing the air filter or spark plug can be handled at home. However, complex issues such as engine overhauls or clutch replacements may necessitate professional service to ensure safety and proper functionality. Always weigh skill level and tool availability against repair complexity when deciding.

Safety Guidelines for Handling Chainsaws

Always maintain a firm grip with thumbs and fingers encircling the handles to reduce kickback. Wear protective gear, including gloves and safety glasses. Ensure proper handling techniques to avoid accidents and injuries. Regularly inspect the chainsaw for damage or wear. Never operate without proper training or precautions to ensure safe and controlled use.

8.1 Proper Handling Techniques

Proper handling techniques are crucial for safe chainsaw operation. Maintain a firm grip with thumbs and fingers encircling the handles to reduce kickback. Stand with a wide stance for stability and keep the chainsaw close to your body. Avoid loose clothing that could get caught. Always operate with both hands and avoid overreaching. Keep the chainsaw at a comfortable height and balance to ensure control and prevent accidents.

8.2 Protective Gear

Protective gear is essential for safe chainsaw operation. Wear a helmet with face protection, safety glasses, and ear protection to guard against debris. Use high-quality gloves for grip and hand protection. Sturdy, chainsaw-resistant pants or chaps and steel-toe boots are crucial to prevent severe injuries. Ensure all gear fits properly and meets safety standards to maximize protection while operating the STIHL 025 chainsaw.

8.3 Emergency Procedures

In an emergency, turn off the engine and secure the chainsaw immediately. Assess for damage using the parts diagram to identify components needing attention. Ensure no further accidents occur by safely storing the saw after the incident. Always prioritize safety and refer to the STIHL 025 parts diagram for guidance on inspections and necessary repairs.

DIY Repair and Assembly

DIY repair and assembly for the STIHL 025 require precise tools and adherence to the parts diagram. Ensure all components are correctly identified and securely fitted to maintain functionality and safety.

9.1 Tools and Equipment Needed

Essential tools include screwdrivers, wrenches, pliers, and torque wrenches. Specialized tools like a piston stop and clutch removal kit may be required. Use the parts diagram to identify specific tools for each component. Ensure all equipment is in good condition to avoid damage or injury; Safety gear like gloves and goggles is crucial for protection during repair and assembly processes.

9.2 Step-by-Step Assembly Guide

Refer to the STIHL 025 parts diagram and service manual for guidance. Start by installing the engine and motor housing, ensuring proper alignment. Next, attach the clutch and spur gear, followed by the chain tensioner. Install the air filter and muffler, then connect the fuel system. Use the diagram to verify each part’s correct placement. Tighten all components according to torque specifications. Finally, conduct a thorough inspection before starting the engine.

9.3 Common Mistakes to Avoid

Common mistakes during assembly include improper alignment of parts, overtightening components, and incorrect installation of the clutch and spur gear. Ensure all parts are lubricated adequately and installed in the correct order. Avoid forcing parts into place, as this can cause damage. Always refer to the parts diagram and service manual for precise instructions to prevent errors and ensure optimal performance.

Compatibility and Interchangeability

Ensure parts are compatible with the STIHL 025 model by cross-referencing the parts diagram. Use genuine or approved aftermarket parts to maintain performance and warranty validity.

10.1 Cross-Referencing Parts

Cross-referencing parts ensures compatibility with the STIHL 025 model. Use the parts diagram to match numbers with genuine or aftermarket components. Verify specifications and fitment to avoid installation issues. This step is crucial for maintaining performance and safety, ensuring that all components work seamlessly together. Always consult the official STIHL catalog or authorized dealers for accurate cross-referencing.

10.2 Aftermarket vs. Genuine Parts

Genuine STIHL parts ensure quality and compatibility, adhering to strict standards. Aftermarket options may offer cost savings but vary in quality. Using the parts diagram, verify specifications to make informed decisions. Always prioritize reliability and safety, especially for critical components like the engine and clutch. Genuine parts often come with warranties, providing added assurance and peace of mind for users.

10.3 Warranties and Guarantees

Genuine STIHL parts often come with manufacturer warranties, ensuring protection against defects. Aftermarket parts may lack such guarantees. Always check warranty terms when purchasing. Using the parts diagram, verify part numbers to ensure compatibility and warranty coverage. Genuine parts typically offer longer warranties, providing assurance of quality and performance for your STIHL 025 chainsaw.

Environmental Considerations

Proper disposal of old parts and eco-friendly maintenance practices are crucial. Using the parts diagram, ensure sustainable repair processes to minimize environmental impact and promote energy efficiency.

11.1 Proper Disposal of Old Parts

Ensure environmentally responsible disposal of worn-out components by recycling metals and safely handling hazardous materials like batteries and oil. Use the parts diagram to identify materials requiring special disposal methods. Always check local regulations and consider recycling options to minimize ecological impact. Proper disposal helps conserve resources and reduces environmental contamination, promoting sustainability.

11.2 Eco-Friendly Maintenance Practices

Eco-friendly maintenance practices for the STIHL 025 involve using biodegradable lubricants, minimizing oil usage, and ensuring proper waste disposal. Regularly cleaning the air filter and muffler improves fuel efficiency, reducing emissions. Referencing the parts diagram helps identify components needing eco-conscious care, ensuring sustainable operation and reducing environmental impact while maintaining performance and longevity of the chainsaw.

11.3 Energy Efficiency

The STIHL 025 parts diagram highlights components that contribute to energy efficiency, such as the air filter and muffler, which optimize engine performance. Regular maintenance ensures lower fuel consumption and reduced emissions. By referencing the diagram, users can identify parts that promote energy-saving operation, enhancing overall efficiency and minimizing environmental impact while maintaining chainsaw functionality and productivity.

Future Trends in Chainsaw Technology

Future trends in chainsaw technology focus on advanced engine designs, smart integration, and sustainability initiatives, enhancing efficiency and reducing environmental impact while maintaining high performance standards.

12.1 Advances in Engine Design

Advances in engine design focus on improving efficiency, reducing emissions, and enhancing durability. Modern engines incorporate lightweight materials, optimized combustion systems, and smart fuel injection, ensuring better performance while minimizing environmental impact. These innovations are expected to redefine chainsaw technology, offering users more powerful, eco-friendly, and cost-effective solutions for their cutting needs.

12.2 Smart Technology Integration

Smart technology integration enhances chainsaw functionality through advanced sensors, Bluetooth connectivity, and mobile app control. These innovations enable real-time performance monitoring, diagnostic feedback, and personalized maintenance alerts. Users can optimize tool efficiency, track usage, and receive guided maintenance recommendations, ensuring prolonged equipment life and improved cutting accuracy. This seamless integration of tech and machinery elevates user experience and operational efficiency.

12.3 Sustainability Initiatives

STIHL prioritizes eco-friendly practices, promoting sustainable forestry and reducing emissions. The 025 chainsaw features energy-efficient engines and recyclable components. Initiatives include biodegradable packaging and partnerships with environmental organizations. By focusing on green technology and responsible resource use, STIHL supports a greener future while maintaining high performance standards in their equipment.

The STIHL 025 parts diagram is an essential resource for owners and technicians, providing clarity on components and repairs. It supports sustainable practices, enhances maintenance efficiency, and ensures safety. By referencing this guide, users can extend the chainsaw’s lifespan and performance, aligning with STIHL’s commitment to eco-friendly innovation and reliable power equipment.